- Components for water heaters

- Magnesium anodes

- Threaded flanges

- Safety groups

- Gaskets

- Light indicators

- Sockets

- Dielectric fittings

- Heating element

- Exaust siphons

- Thermometers

- Thermostats

- Safety valves

Components for water heaters - Components for thermal plants

- Safety instruments

- Sheaths

- Manometers

- Manual drain cocks

- Pressure cock with gauge holder

- Coils

- Thermomanometers

- Ball valves

- Safety valves

- Airvent valves

- Safety valves

Components for thermal plants - Components for radiators and home appliances

Components for radiators and home appliances

- Components for plumbing systems

- Components for solar plants

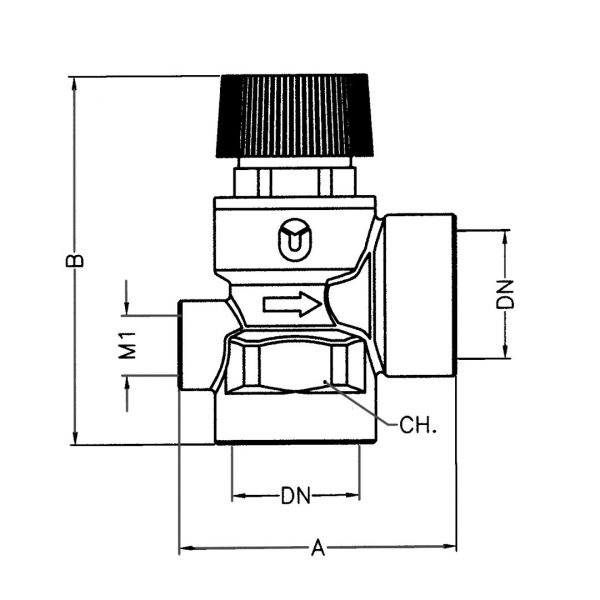

Diaphragm safety valve for boilers less to 30.000 kcal/h

Item number: 210-3

Category: Safety valves

CE 2014/68/UE/P.E.D

Specifiche tecniche

| A | 47 |

| B | 71 |

| M1 | 1/4" |

| CH | 31 |

| CALIB. | 1,5÷8 bar |

| PZ. | 8/72 |

| kg | 15 |

| ART | 210 |

| DN | 3/4" FF |

Safety valves for heating and plumbing systems

Overview and function

Safety valves are typically used for controlling the pressure in heat generators (heaters, solar panels, boilers) in heating systems, plumbing systems and water systems. When the set pressure is reached, the valve opens and vents, impeding the system from reaching dangerous limits for the generator and for the compo- nents in the system itself.

Ordinary safety valves used on generators rated below 35 kW (30.000Kcal/H).

Technical characteristics

- Diaphragm safety valve

- Body: OT58 UNI EN 12165 CW617N

- Top: Nylon caricato vetro 30%

- Diaphragm: EPDM

- Spring: Acciaio UNI 3823

- Control knob: ABS

- Nominal pressure: PN10

- Temperature range 5÷120°C

- Valve calibration: 2,5÷8 bar

- DN 1/2″ seat diameter: Ø 13mm

- DN 3/4″ seat diameter: Ø 13 mm

- Manual opening by red knob

- Gauge coupling: 1/4 Gas_F

Installation

Before safety valves are installed, they must be correctly sized by a specialised technician, according to the standards in force and for the specific applications. They must not be used for purposes other than the one they are designed for. Only qualified technical personnel may install safety valves according to the standards in force. Safety valves must be installed respecting the flow direction indicated on the valve body.

Certification

CE mark TP: double function relief valves comply with the essential safety requirements of Directive 97/23/EC concerning pressure equipment (also called PED). They are therefore classified as category IV and are equipped with the CE mark.

Product certification in accordance with European Standard EN 1490

The European standard EN 1490: 2000, entitled “Valves for buildings”

- Combined temperature and pressure relief valves

- Tests and requirements, describes the constructional and performance specifications that TP relief valves must have.

NB:

- Valve calibration from 2.5 to 8 bar, on request.

-

Possibility of creating alternative versions to drawings on specific customer request.

Related products

-

Safety valvesView product

Double function safety valve temperature and pressure

-

Safety valvesView product

Diaphragm safety valve for boilers less to 30.000 kcal/h

-

Safety valvesView product

Diaphragm safety valve for boilers less to 60.000 kcal/h

-

Safety valvesView product

Diaphragm safety valve for boilers less to 30.000 kcal/h

- View product